Step 1

Material Inspection

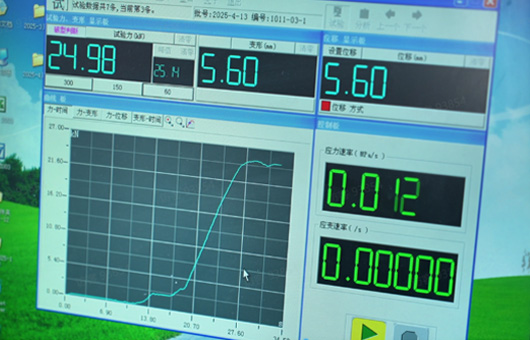

All steel, aluminum alloy, and insulation materials undergo both physical and chemical testing.

All steel, aluminum alloy, and insulation materials undergo both physical and chemical testing.

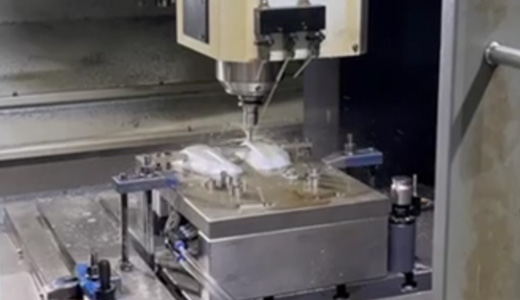

We independently develop multiple mold models to ensure precise connection structures.

This includes stamping, CNC machining, polishing, electroplating, spraying, and heat treatment.

Each product undergoes load capacity and operational flexibility testing.

Multiple batches undergo random inspections and full appearance and functionality inspections before shipment to ensure consistency.